Adsorber AAC-500 for air purification at sewage pumping stations

Atmospheric pollution with hydrogen sulphide and other unpleasant or strong smelling gaseous compounds is a problem faced by sewage pumping stations and many other production and non-production facilities. Our solution is the AAС-500 adsorption device with catalytic cleaning. Undesirable impurities are eliminated by this device through the use of an adsorbent in form of activated carbon containing certain catalytic impurities and additives. That is, the contaminated air enters the working chamber through the gas duct where it passes through the activated carbon layer that absorbs the hydrogen sulphide. Thus, clean air meeting the requirements of the environmental legislation is the outflow from the adsorber.

Technical specifications of the ААС-500

The environment where the device is used is corrosive and has the hazard class 2 according to GOST (All-Union State Standard) 12.1.007-76 „Occupational safety standards system. Noxious substances. Classification and general safety requirements“. It is non-explosive and non-flammable.

| Technical specifications / Model | AAC-500 |

| The capacity of the device in terms of the purified gas flow is as follows (in m3/h): |

|

| Maximum hydraulic resistance of the device, Pa | 1000 |

| Maximum allowable vacuum in the device casing, Pa | 5000 |

| Gas temperature at the entrance, oC |

|

| Maximum relative humidity of inlet gas,% | 90 |

| Maximum concentration of hydrogen sulphide, g/nm3 |

|

| Mass of device without sorbent, kg | 170 |

| Maximum mass of sorbent, kg | 90 |

| Adsorbent | As a sorbent, activated carbon impregnated with potassium iodide is used, developed and tested under operating conditions at the sewage pumping station.

The lifetime of the adsorbent is at least 1,5 – 2 years. |

| Units of the device | All units of the device are made of 12Х18Н10Т* stainless steel, profile products are made of 08Х18Н10** stainless steel (analogue of AISI 304).

The material of the gaskets is the 1Н-I-ТМКЩ-С-3*** sheet, GOST (All-Union State Standard) 7338-90 „Rubber and rubber-fabric sheets. Specifications“. |

| Adsorber warranty | 1 year |

| Adsorber cost | from 7 000 $ |

| Adsorbent cost | from 10 $ for kg |

| Make a request | Order now |

*12Х18Н10Т is a stainless steel, X is chrome (Cr), H is nickel (Ni), Т is titanium (Ti). This steel contains 0,12% of carbon, 18% of chrome, 10% of nickel and not more than 1 – 1,5% of titanium.

**The steel of marking 08Х18Н10 contains 0,08% of carbon, 18% of chrome and 10% of nickel.

***1Н-I-ТМКЩ-С-3 is a rubber plate: category 1, manufacture method Ф, type I, marking ТМКЩ (heat frost acid alcaline), hardness degree C, thickness 3 mm.

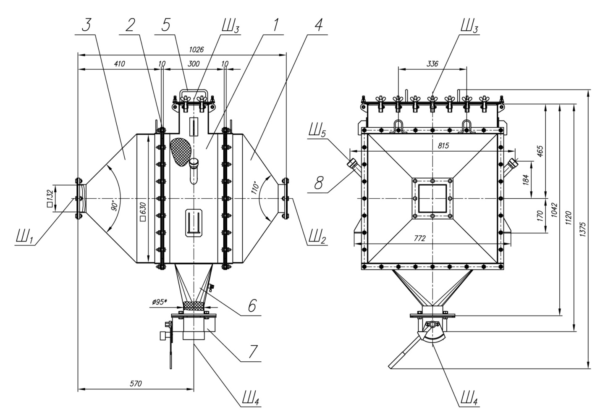

Activated carbon impregnated with potassium iodide and other compounds is used as a sorbent. In the device, the adsorption method for purifying gas from gaseous sulphur compounds is implemented. The gas stream that has to be cleaned enters the diffuser and is evenly distributed over the sorbent layer section. Hydrogen sulphide and other foul-smelling gaseous substances are absorbed by the sorbent, and the purified gas enters the flue through the reducer and then flows into the fan.

The AAC-500 adsorption device has a number of features that favorably distinguish it from similar devices.

1. Since we developed this product, we have the expertise to:

- modify it for specific premises and operating requirements

- provide high-quality and prompt service

2. Relatively low capacity of the unit means:

- lower cost

- compact dimensions suitable for small spaces

- less quantity of adsorber is needed to fill the working chamber

For a larger volume of purified air or room size, we offer a more powerful model – the adsorption device with catalytic cleaning.

3. A simple but effective design without marketing excesses:

- guarantees a reasonable price

- eliminates leakage of polluted air and poor quality cleaning

allows you to quickly assess the sorbent condition through special sampling ports - allows the manual replacement of absorbent material, which is convenient for premises where it is not possible to install special mechanisms

- does not require special training for employees to work with the unit.

Functionality. At small sizes, the adsorption unit is able to purify a large volume of air. In addition, thanks to its sorbent (impregnated with potassium iodide of not less than 2% and having a high catalytic capacity), unpleasant odors can be eliminated at a sewage pumping station.

In order to enable a long and effective lifetime of the ААС-500 unit with catalytic cleaning you need to keep a few simple rules:

- Install the unit in a heated room that is adequately protected from the risk of explosion or fire.

- Ensure the presence of an active ventilator, as this is necessary for operation under vacuum.

- A straight section of the gas flue before the gas flows into the device should be at least 0,6-0,8 meters long;

- The maximum air speed allowed in the supply and outlet sections is 8 m/s, and in the working chamber 0,4 m/s.

- The frequency of adsorbent replacement depends on the concentration of gaseous impurities in the air, so you need to frequently monitor adsorbent condition.

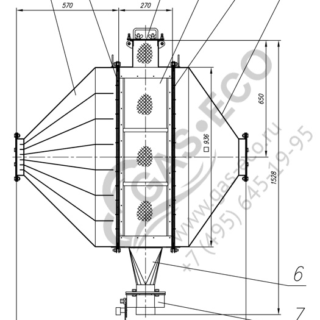

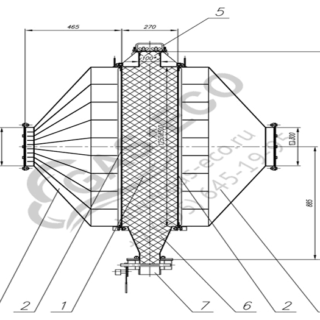

1 – working chamber; 2 – lattice; 3 – diffuser; 4 – reducer; 5 – feed door for the sorbent; 6 – spent adsorbent hopper; 7 – butterfly valve; 8 – samples collection nozzle

The ААС-500 adsorption device with catalytic cleaning is an intellectual property, therefore it can be ordered only at our company.

We guarantee:

- design of the device accounting for the characteristics of the environment and room parameters, where it operates

- expedited manufacturing

- installation and commissioning

- conducting laboratory tests

- advice and technical support

For detailed information on the technical and operational characteristics of the ААС-500 and the terms of cooperation:

- Call +7 (495) 6451995; or +7 (903) 7080254; or

- Complete and submit the feedback form.