Adsorber ААС-2800 for air purification at sewage pumping stations

We present for your consideration our own development, the АСС-2800 adsorption unit (with catalytic purification), designed for purification of gases by catalytically removing hydrogen sulphide, mercaptan and other foul-smelling gaseous compounds.

Our АСС-2800 adsorbtion-catalytic cleaning device passed the procedure of mandatory declaration of compliance with the requirements of the Technical Guidelines of the Customs Union 010/2011 “On the Safety of Machinery and Equipment.” The confirming entry in the Unified Register of Registered Declarations of Compliance is posted on the website of the RusAccreditation (Federal accreditation agency). The declaration can also be found here. The certificate of conformity N 0250255 with validity until 06.06.2021 has been obtained.

In the process of developing the device, we considered all aspects of the working conditions, as well as the shortcomings of competing products. As a result, our adsorption device was developed with its own unique design features and as a result it has unique technical and operational characteristics that may seem to be incompatible with each other at first glance.

Technical specifications of the AAC-2800 adsorption-catalytic cleaning device

The environment where the device is used is corrosive. It has the hazard class 2 according to GOST (All-Union State Standard) 12.1.007-76 „Occupational Safety Standards System. Noxious Substances. Classification and General Safety Requirements“ and is non-explosive and non-flammable.

| Technical specifications / Model | AAC-2800 |

| The capacity for purified air, m3/h |

|

| Maximum hydraulic resistance of the device, Pa | 1000 |

| Maximum allowable vacuum in the device casing, Pa | 5000 |

| Air temperature at the entrance to the device, oC |

|

| Maximum relative air humidity, % | 90 |

| Maximum concentration of hydrogen sulphide, g/Nm3 |

|

| Mass of the device without adsorbent, kg | 620 |

| Mass of adsorbent, kg | 400 |

| Adsorbent | As a sorbent, activated carbon impregnated with potassium iodide is used, developed and tested under operating conditions at the sewage pumping station.

The lifetime of the adsorbent is at least 1,5 – 2 years. |

| Units of the device | All units of the device are made of 12Х18Н10Т* stainless steel, profile products are made of 08Х18Н10** stainless steel (analogue of AISI 304).

The gasket material is 1Н-I-ТМКЩ-С-3*** sheet, GOST (All-Union State Standard) 7338-90 „Rubber and rubber-fabric sheets. Specifications“. |

| Adsorber warranty | 1 year |

| Adsorber cost | from 25 000 $ |

| Adsorbent cost | from 10 $ for kg |

| Make a request | Order now |

*12Х18Н10Т is a stainless steel, X is chrome (Cr), H is nickel (Ni), Т is titanium (Ti). This steel contains 0,12% of carbon, 18% of chrome, 10% of nickel and not more than 1 – 1,5% of titanium.

**The steel of marking 08Х18Н10 contains 0,08% of carbon, 18% of chrome and 10% of nickel.

***1Н-I-ТМКЩ-С-3: category 1, manufacture method Ф, type I, marking ТМКЩ (heat frost acid alcaline), hardness degree C, thickness 3 mm.

NOTE:

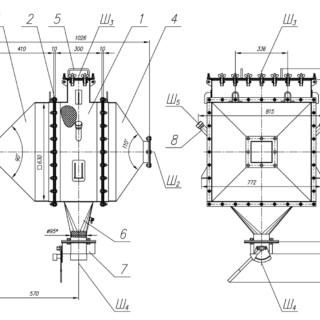

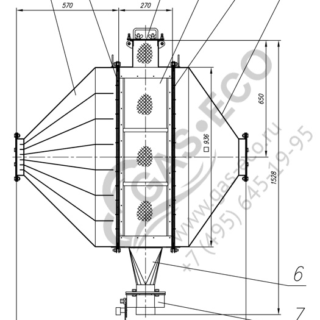

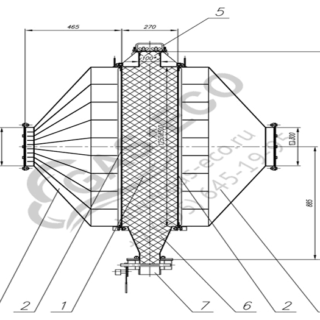

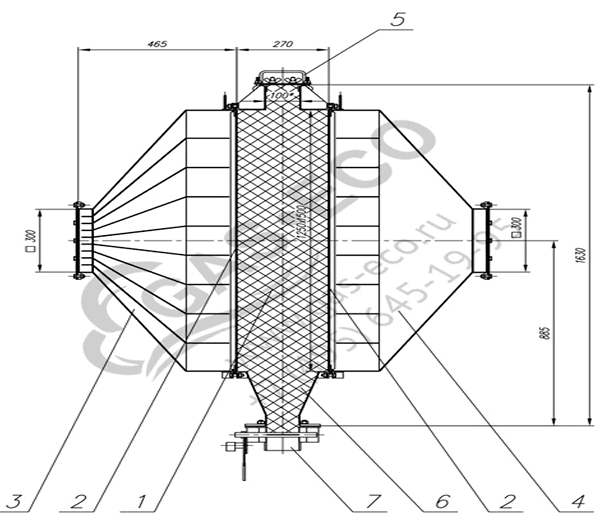

Dimensions of the device are approximate. For precise dimensions it is necessary to send a request or to contact our Engineering department.

At our company you can order:

- the standard AAC-2800 adsorption unit, or the design can be modified to meet special requirements with individually customized parameters,

- manufacture of the unit from high quality materials,

- installation, adjustment and testing of the gas cleaning system

- after-sales service, that includes technical support on both operation and maintenance.

To place an order:

- Call +7 (495) 6451995; +7 (903) 7080254 or

- Complete and submit the feedback form.

The AAC-2800 adsorption device has a number of features that favorably distinguish it from similar devices.

Compactness. The device can be installed in small rooms, although the mass of the adsorbent required for effective purification is about 400 kilograms. This became possible due to the unique design of the device’s working chamber, which is divided into three sections, by two longitudinal partitions. Each section has a separate spent adsorbent hopper, from which it is possible to consecutively discharge the spent adsorbent manually, without using special mechanisms (augers or conveyors).

Functionality. Despite its small size, the adsorption unit is able to purify a large volume of air. In addition, thanks to its sorbent (impregnated with not less than 2% potassium iodide which has a high catalytic capacity), unpleasant odors can be eliminated (in applications such as sewage pumping stations).

Reliability. The 150 mm extension of the filling hatch facilitates the prevention of hollow formations in the working chamber as the sorbent layer shrinks during operation. Hollow formations would otherwise allow polluted gas to bypass the sorbent layer thereby reducing the efficiency of purification.

Ease of operation and maintenance. Operation of the АСС-2800 adsorption unit with catalytic cleaning does not require special skills and qualifications. The design of the device provides special nozzles through which it is easy to take samples of the adsorbent to check the degree of its contamination. The waste sorbent can be discharged manually, alternately from each spent sorbent hopper.

1 – working chamber; 2-lattice; 3 – supply; 4 – outlet; 5 – hatch for loading the adsorbent; 6 – spent adsorbent hopper; 7 – butterfly valve

The АСС-2800 adsorption device is an intellectual property, therefore it can be ordered only from our company.

We guarantee:

- design of the device accounting for the characteristics of the environment and room parameters, where its operation is expected

- manufacturing in the minimum term

- installation and commissioning

- conducting laboratory tests

- advice and technical support

- warranty service

The principle of operation of the АСС-2800 adsorption device

The adsorption method for gas purification and elimination of gaseous sulphur compounds is implemented in the ACC-2800. The gas to be purified is uniformly distributed over the sorbent layer. Hydrogen sulphide, mercaptan and other foul-smelling gaseous substances present in the gas are absorbed by the activated carbon and then the purified gas enters the gas flue through the outlet and goes into the environment.

There are several conditions under which the operation of the device will be most effective:

- Ensure the presence of an exhaust fan, as this is necessary for operation under vacuum;

- A straight section of the gas flue before the gas flows into the device should be at least 1,2-1,6 meters long;

- The maximum air speed allowed in the supply and outlet sections is 8 m/s, and in the working chamber 0,4 m/s;

- The frequency of adsorbent replacement depends on the concentration of gaseous impurities in the inlet air, so you need to frequently monitor adsorbent condition.

For detailed information on the technical and operational characteristics of the АСС-2800 and the terms of cooperation:

- Call +7 (495) 6451995; or +7 (903) 7080254; or

- Complete and submit the feedback form.