Adsorbers

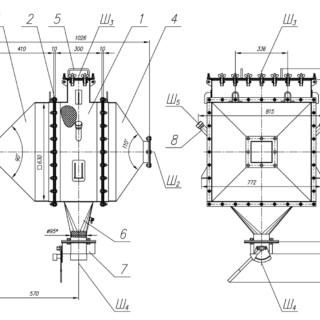

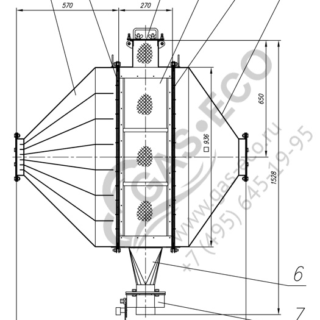

To clean harmful gaseous impurities from aggressive process gases, we recommend using adsorber models AAС-500, AAС-1000, AAС-2800 or AAC-5000. These adsorbers are designed for cleaning the air released from sewage plants. They have process gas flow rate capacities of 300-500 m3/h, 1000-1200 m3/h, 2500-2800 m3/h and 4800-5000 m3/h respectively.

You can order the AAC-500, AAC-1000, AAC-2800 or AAC-5000 with the following services:

- equipment manufacturing

- transportation, if your company is located in the Russian Federation and beyond its borders

- installation and commissioning

- preparation of all necessary documents

Our production

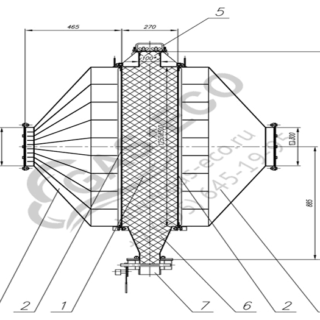

Our specialists produce purification units for dust removal and gas scrubbing in full compliance with All-Union State Standard (GOST) and Construction Rules and Regulations (SNiP). The standard AAC series of adsorbers utilizes a rectangular housing made of high quality 12X18H10T* stainless steel. In the upper part there is a hatch with a removable lid for loading fresh adsorbent (activated carbon impregnated with potassium iodide and other additives for capture of hydrogen sulphide and other bad-smelling substances). In the lower part there is a pyramidal hopper and a slide gate to remove the spent material. The untreated gas is supplied through a lateral flue, equipped with a flat-type input distributor with dividing partitions (diffuser), and exits through the outlet flue (reducer). Both channels are rigidly connected to the housing.

The adsorption units are characterized by their simple design, easy maintenance and replacement of the adsorbent.

The principle of adsorber’s functioning is quite simple. The contaminated gas flows through the diffuser into the chamber and flows uniformly through the adsorbent-catalyzer layer, which adsorbs harmful particles. Next, the purified gas goes into the environment through the reducer.

In the device housing there is a chamber with side walls made of wire mesh with square cells, as well as horizontal stiffening ribs. The chamber is filled with the adsorbent. This design prevents deformation of the uniform adsorber layer by the gas flowing from the diffuser to the reducer.

The adsorbent for the AAC-500, AAC-1000, AAC-2800 and AAC-5000 adsorbers can be delivered both separately and at the initial installation of the equipment, at the request of the Customer.

In order to learn more about our adsorption units, their principle of operation and operating conditions or to buy our products, you can send us an online application or call us at: 8-495-645-19-95 or 8-903-708 -02-54 (Moscow time).

*12Х18Н10Т is a stainless steel, X is chrome (Cr), H is nickel (Ni), Т is titanium (Ti). This steel contains 0,12% of carbon, 18% of chrome, 10% of nickel and not more than 1 – 1,5% of titanium.